HYDRA EVO AUTOCLAVE with printer - 15 litres - 230V

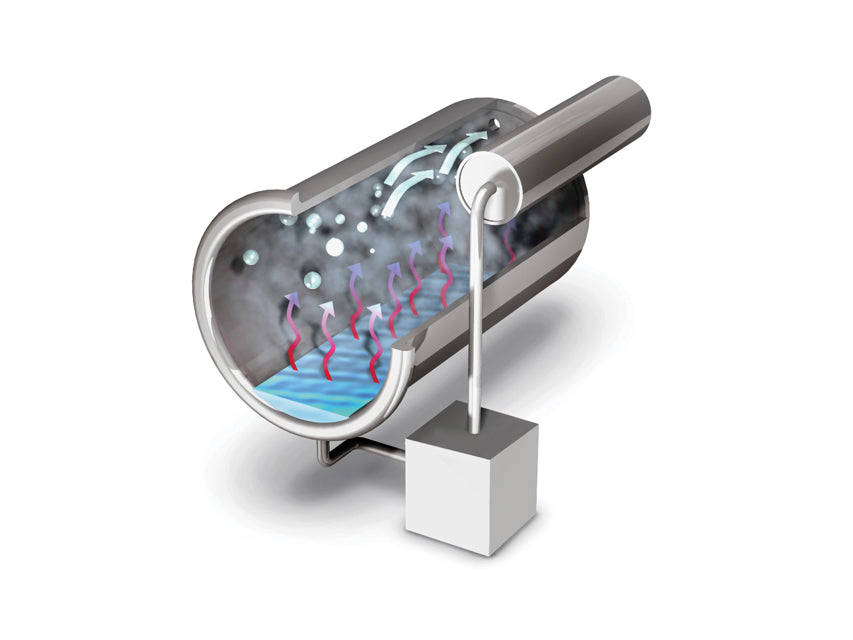

Autoclave that uses steam to sterilize unwrapped devices. Closure system with a pivot for operator safety. Thermodynamic Autoclave that uses steam to sterilize unwrapped devices. Closure system with a pivot for operator safety. Thermodynamic device for ejecting "cold" air locks.

Read more

Out of stock

HYDRA EVO AUTOCLAVE with printer - 15 liter - 230 V

Automatic steam autoclave for the sterilization of unwrapped instruments. Closure system with an operator safety pivot.

Thermodynamic system for the ejecting of the "cool" air locks.

Two sterilization cycles: 121°c and 134°C

Automatic phases of pre-heating, sterilization cycle and drying.

Pre-set non-modificable cycles

All cycles are pre-set at the factory and guarantee perfect and safe sterilization of treated materials. There is no way the operator can manipulate or after the cycles, and this against risks deriving from human error.

Pre-set temperatures

The temperatures set for our autoclave cycles are 134°C and 121°C.

The 134°C cycles are normally used for the sterilization of solid and ferrous materials.

121°C cycles are normally used for sterilization of thermoplastic and delicate materials.

Water tanks

HYDRA EVO is equipped with an internal tank for pure water and another for used water. Each tank is equipped with probes to detect the minimum and maximum water levels.

Fully automatic cycles

All cycles are fully automatic, with all steps managed by the leading-edge computer board with a powerful microprocessor. Each step (vacuum, preheating, exposure time, drying) is automatically monitored, assisted and handled. There is no need for human intervention in cycle management

Safety on the door

Each door is equipped with 2 locks:

- a mechanical one which does not open when pressure is exerted

- a dynamic one, operating with a special form of door seal

Built in printer

Built in printer for the registration of cycles carried out.

Safety devices installed

- certified safety valve

- PED on sterilization chambers

- insulation of the chamber with certified ceramic material

Controls of the autoclave

- control of the water that enters into the chamber

- Safety Thermostat

- Time Control

The sterilization chamber is completely stainless steel AISI 304 and it is heated by a band shaped heating element which grants uniformity of the heat.

Supplied with four aluminium trays and one key for their extraction.

User manual avalab1e in English, French, Italian, Spanish.

TECHNICAL SPECIFICATIONS

• Stainless steel chamber: Ø 24.5 x 32 cm

• External size: 51 x 39 x 59 cm (W x H x D)

• Net weight: 54 Kg

• 2 sterllization cycles: 121°C and 134°C

• Operating Voltage: 230 V ± 10% - 50/60 Hz

• Power consumption: 1500 W

• Class N

• Made in Italy

• Warranty: 1 year

CYCLES NOT WRAPPED 121°C

• Materials:

- Fragile solids

- Rubber solids.

- Glass

- Turbines if indicated by producer

• Sterilization time: 35 min.

• Max Load: 4 Kg (1 Kg load in any tray)

• Working pressure: 1.2 ÷ 1.3 bars

CYCLES NOT WRAPPED 134°C

• Materials:

- Stainless metal solids

- Turbines if indicated by producer

• Sterilization time: 21 min.

• Max Load: 4 Kg (1 Kg load in any tray)

• Working pressure: 2.1 ÷ 2.2 bars